SELECTION OF CABLE TRAYS

A) CABLE MANAGEMENT SYSTEM SELECTION:

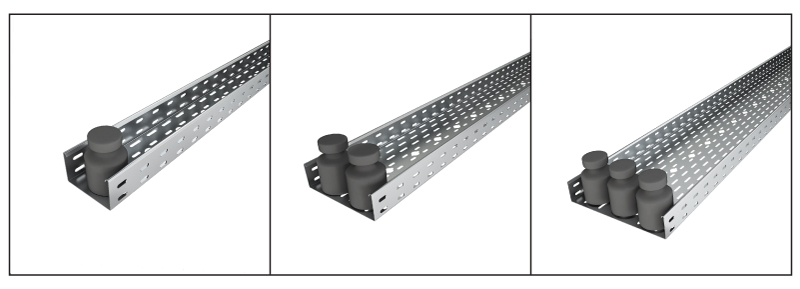

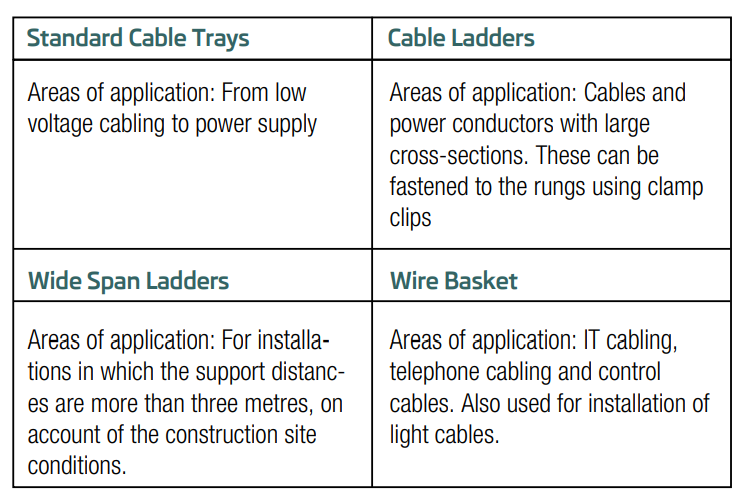

To select the perfect cable support system, you need to know which type of cables are to be laid and construction

site conditions. For different applications, Kıraç Metal can offer tailor-made system solutions:

B)CALCULATING VOLUME OF THE CABLES

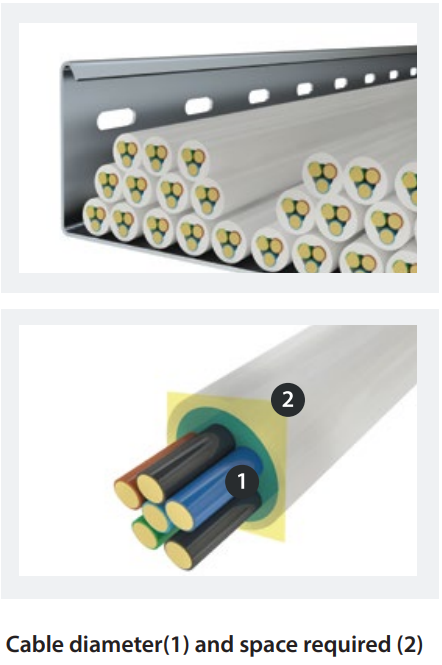

The cable volume is an important criterion for the selection

of the correct cable support system; for which there must

be sufficient space in the cable tray. As the cables are

never packed tightly together or are absolutely parallel, it is

not enough to base the volume calculation solely on the

cable diameter.

A realistic calculation is provided by the formula (2r)2,

where 2r is the diameter of cable. This formula should be

applied to all cables to be installed and they should all be

summed up. Later %30 additional capacity should be

added for future requirements. (see fig.1)

STANDARD CABLE DIAMETERS

Important: These are average values which may vary for different manufacturers.

Please refer to the manufacturer’s specifications for the exact values.

C) CALCULATING WEIGHT OF THE CABLES:

Most cable manufacturers offer a very accurate method of calculating cable weights, and appropriate weights per

cable can be obtained directly from manufacturers.

The average load capacity of a cable tray can be calculated approximately using experience values. For a system

with a side height of 60 mm, a value of 15 kg per 100 mm width is valid for each meter of cable tray or cable

ladder.

D) MAXIMUM LOADING CAPACITY

There is a general rule to calculate maximum loading capacity of a cable tray. In many projects, this rule is used

as an initial assumption for measuring and modifying the support structure. Calculation principle: This principle

calculates the cross-section area of a cable tray. It is assumed that a full cable tray has a cable density of 0.28

kg/cm2. Example: The cross-section area of a 50mm x 300mm cable tray (i.e. 5 x 30 cm) is 150 cm2.

(considering inner dimensions). As a general rule, the resulting loading capacity is 0.28 x 150 = 42 kg/m2.